We have begun printing our small collection of holiday cards for this year! We have 4 completely awesome designs that I will feature in an upcoming blog. One of these designs is a card we're calling The Snowy Owl. I decided to document the process of these from initial sketch to final card. I've previously blogged about the process of engraving and editioning a block. These cards are being made from a polymer plate, so it's a blog about the OTHER way we make stuff around here!!

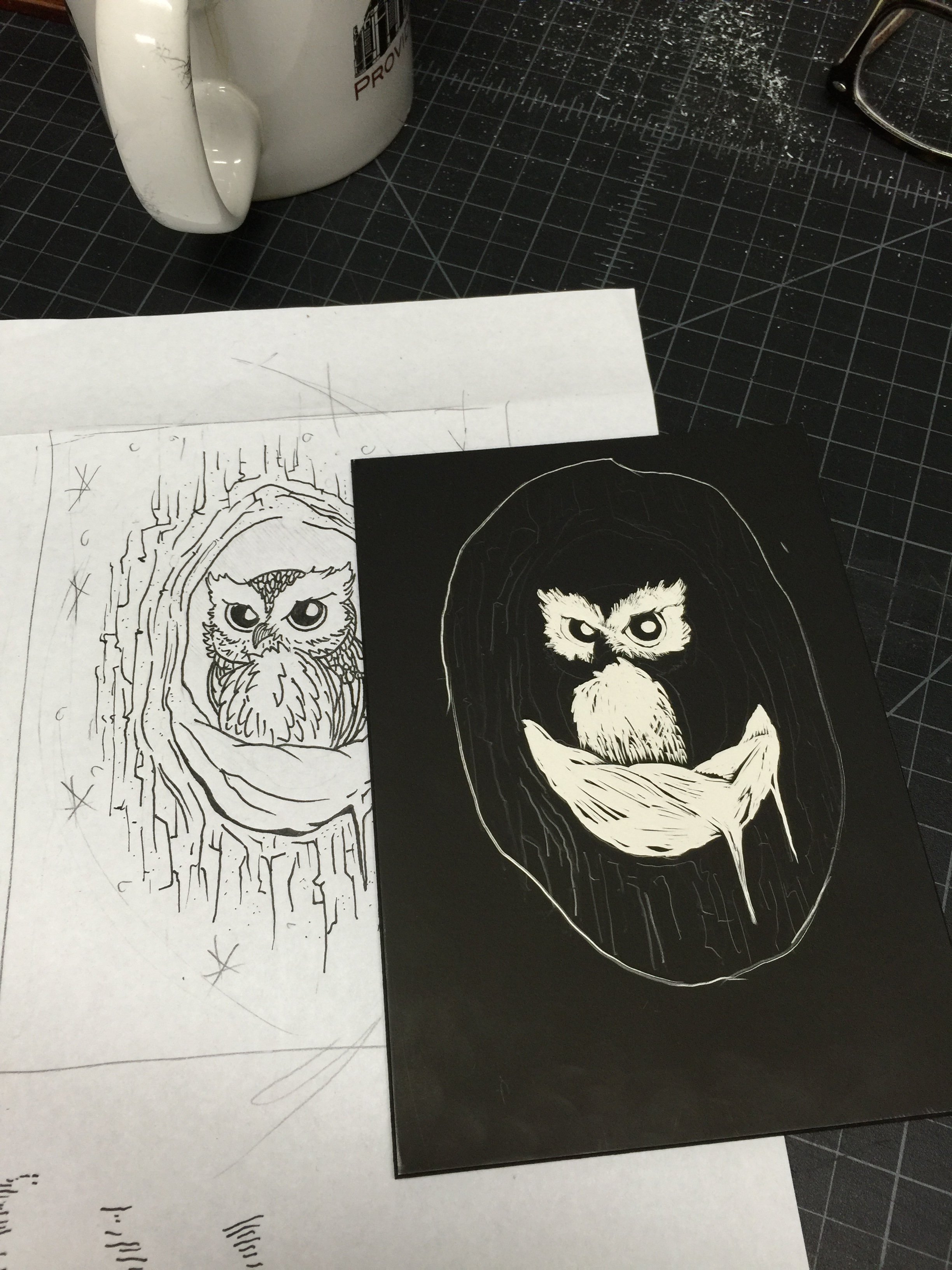

The card started with a sketch. I wanted to make a scratch board illustration of this guy, so I lightly transferred the pencil sketch to the black scratch board and started scratching away!

After a few hours, the scratch board was complete. The image was then scanned into our computer and edited in Adobe Illustrator. Then that file was sent to Boxcar Press, who process the image into a plastic polymer plate for printing.

The plate arrived along with a proof print to see what the image looks like on paper. It wild to see how fine some of those little lines are in the actual plate. Boxcar is the best!

The plate is adhered to the press bed. Blue tape and the small tab to the right in this picture help with aligning the paper when printing. The plate is inked and the Cotton paper is placed on top of it. Then it gets run through the press!

Here is the paper being lifted off of the plate! A beautiful, clean, very deep impression!

DEEP!

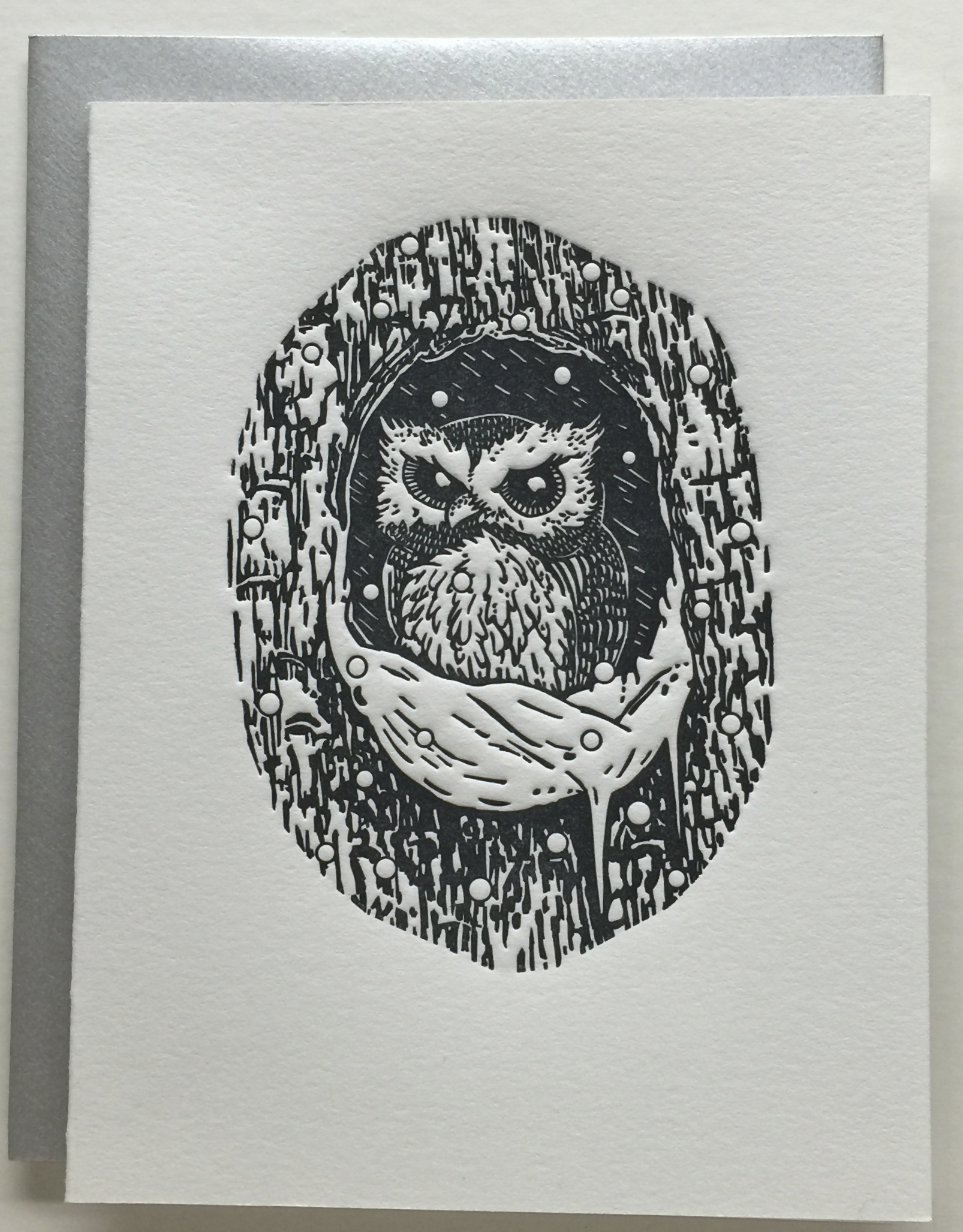

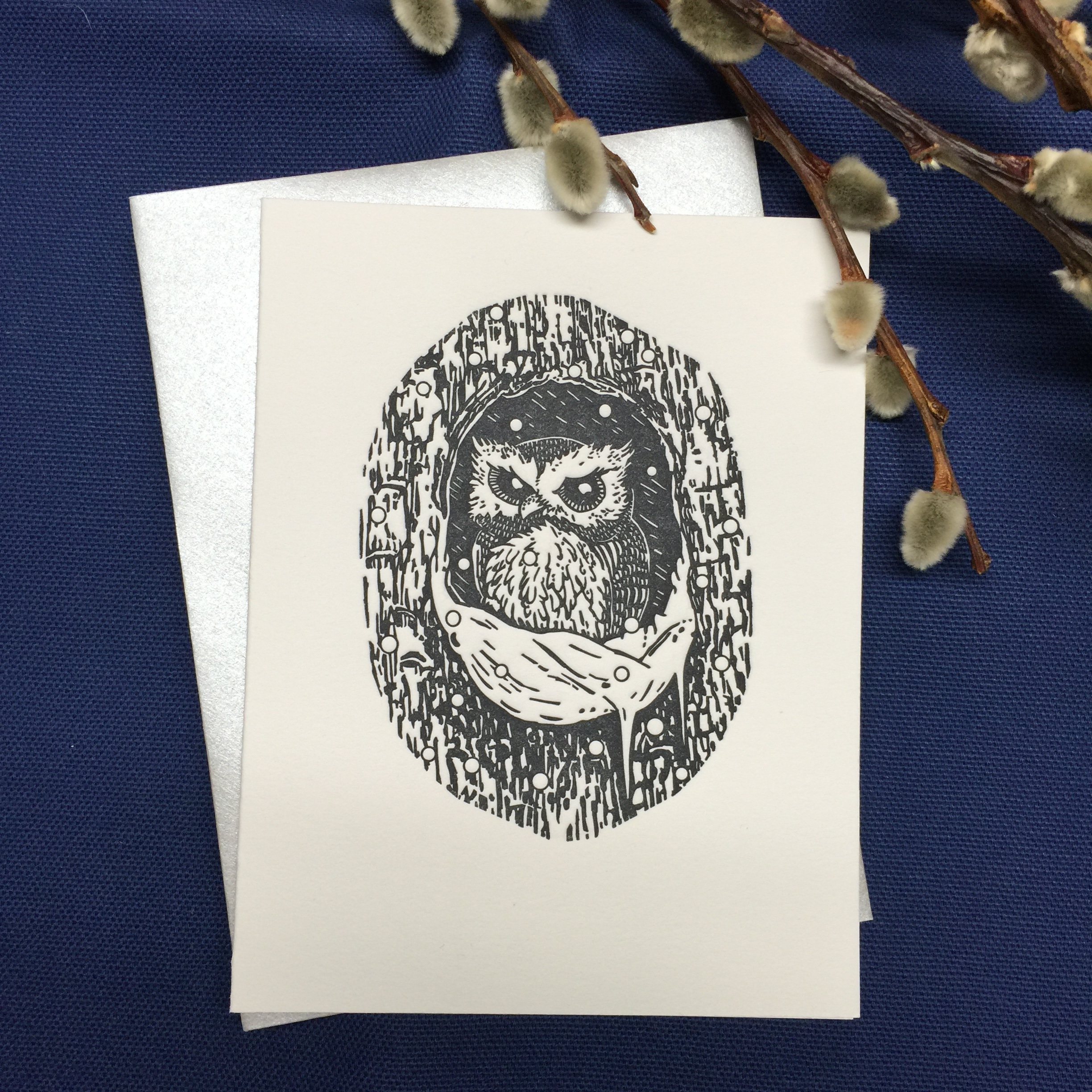

That's a wrap! The A2 Size cards are printed in a dark denim blue on 100% cotton 110lb Lettra paper and are matched up with metallic silver envelopes.