Designing and Printing Posters for Tor Johnson Records

On May 12, 2012 Tor Johnson Records celebrated their 10 year anniversary show at AS220 in Providence, RI. Tor Johnson Records is a local record label run by Paul Dechichio. It was a huge night, with 8 bands playing hard, fast sets and destroying the place. TJR had the show filmed for a future release, and over the past few months they have been editing and putting together the DVD from that killer night. In classic Tor Johnson fashion, they had a gigantic concert to celebrate the release of the DVD.

I was asked to make the posters for this release show, and I jumped at the chance to work with Paul and the Tor Johnson crew. Here's how I made them!

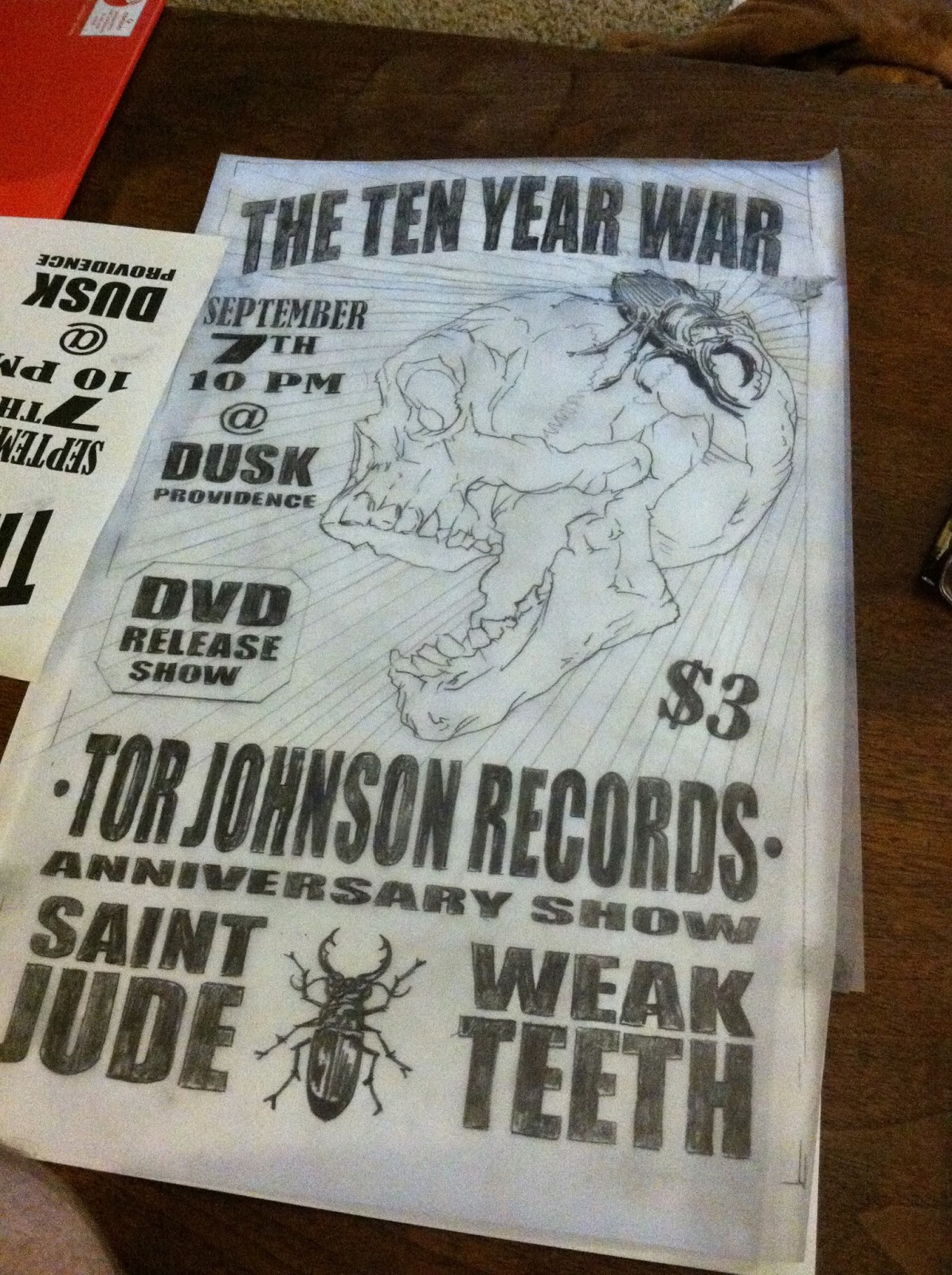

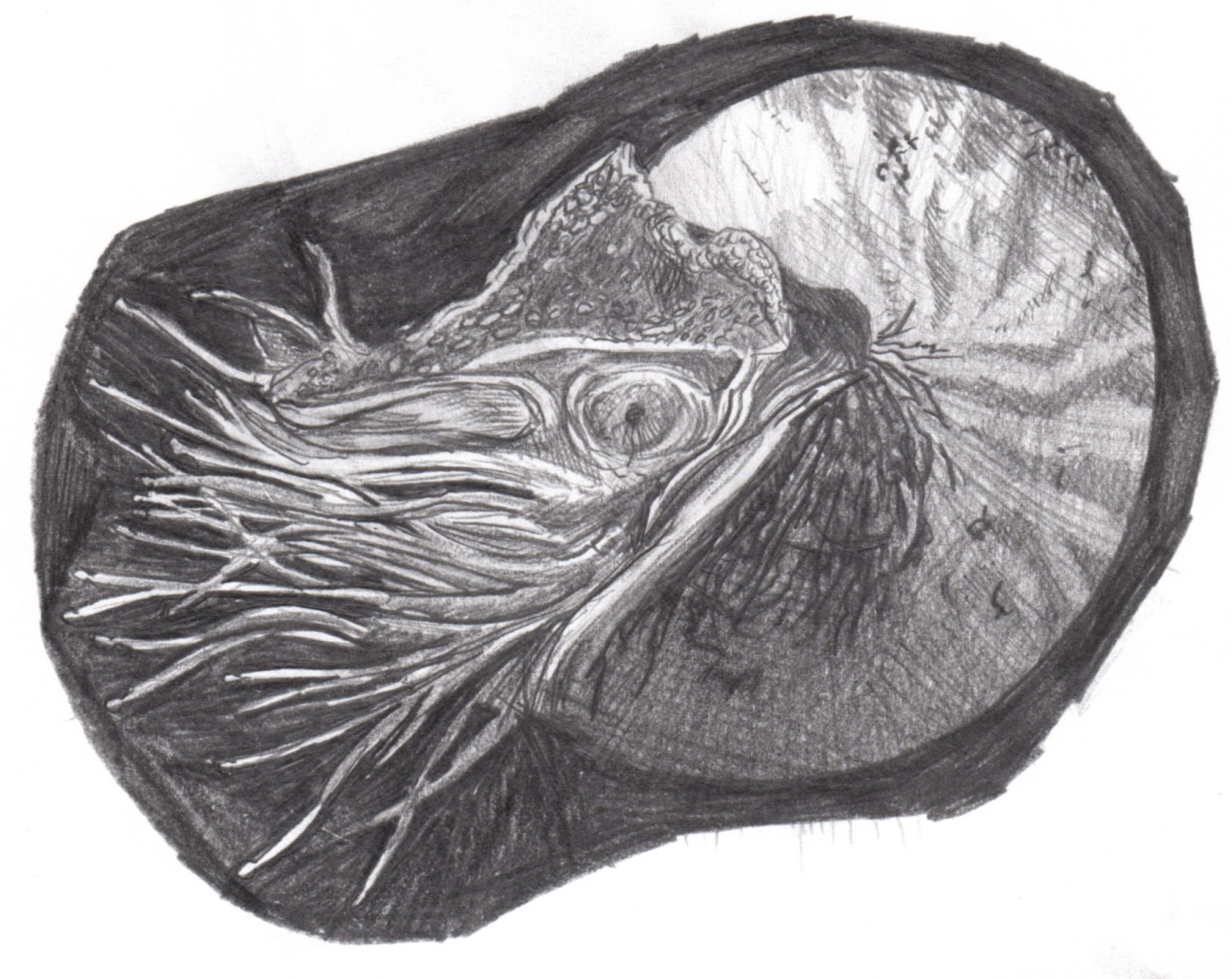

It all started with a concept and a drawing. I decided to make the poster 11 x 17 in. and began by drawing the poster to scale in pencil. Who doesn't love a screaming skull and stag beetles?

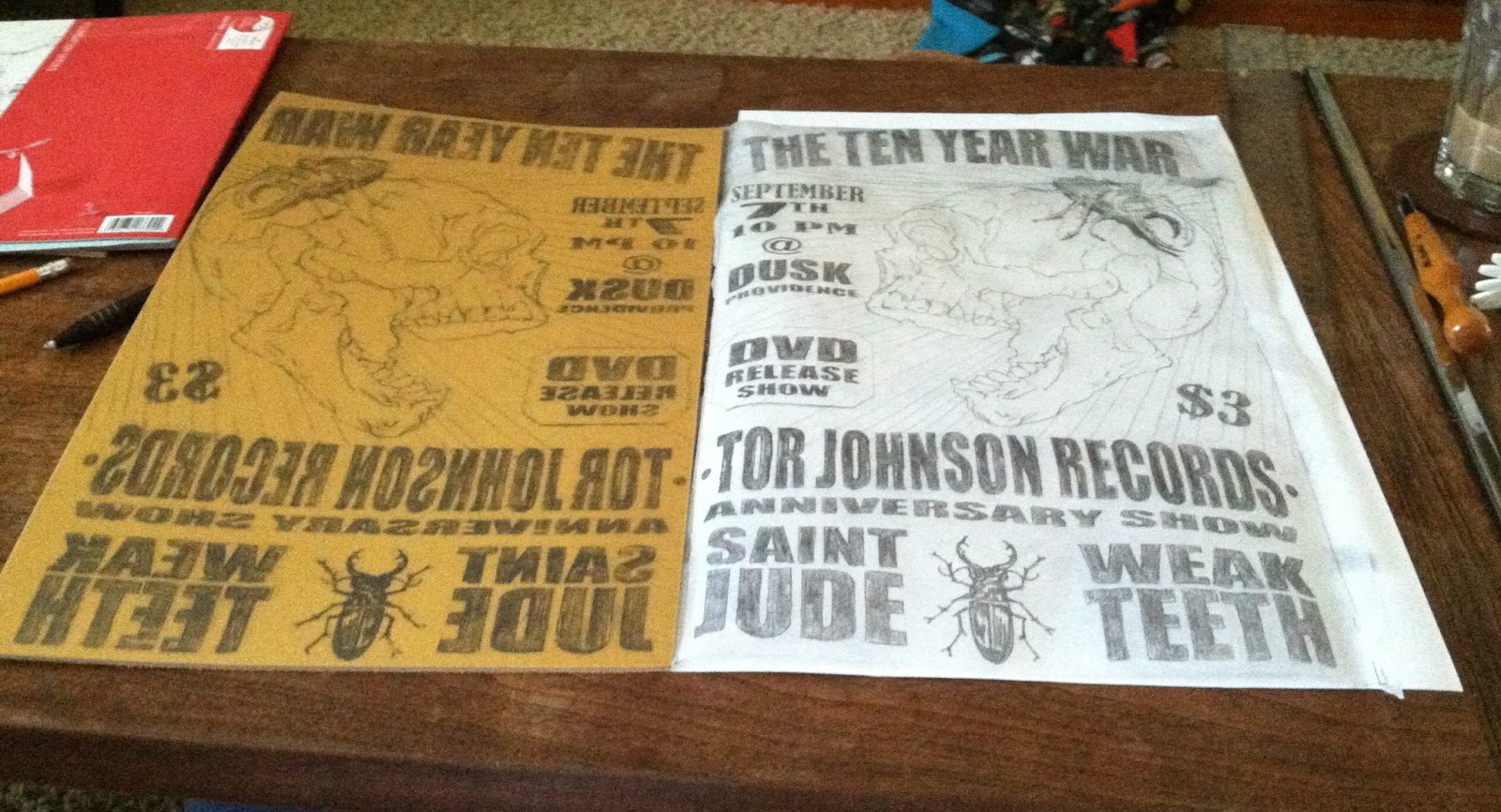

The next step was transferring the drawing onto the linoleum block backwards. I find the easiest way to do this is to make your drawing in soft pencil. Then place it pencil side down on top of the linoleum and simply burnish the back of the drawing. The image transfers clean crisp, and most importantly in reverse!

A Marker helps refine the lines.

The V-Gouge in Action.

I inked some details into the skull and started carving the linoleum. The process basically involves carving away any part of the linoleum block that you do not want to print. What remains is the lettering and images. I use different types of chisels, gouges and knives to remove the linoleum.

Here is the linoleum block after 18 hours of cutting. All that remained was the information that would be printed. I rolled a thin layer of black ink over the surface to see if there were any areas that still needed to be cut.

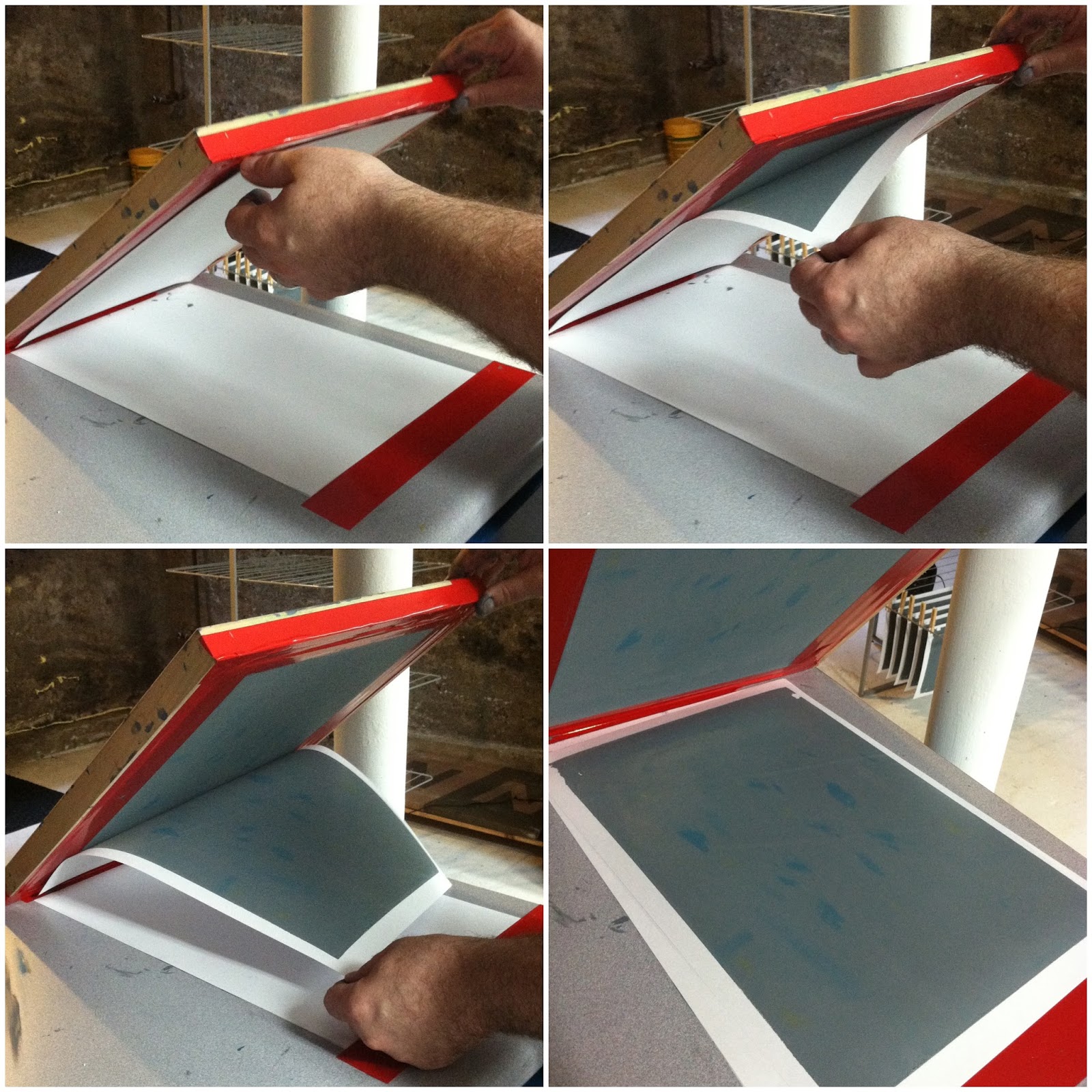

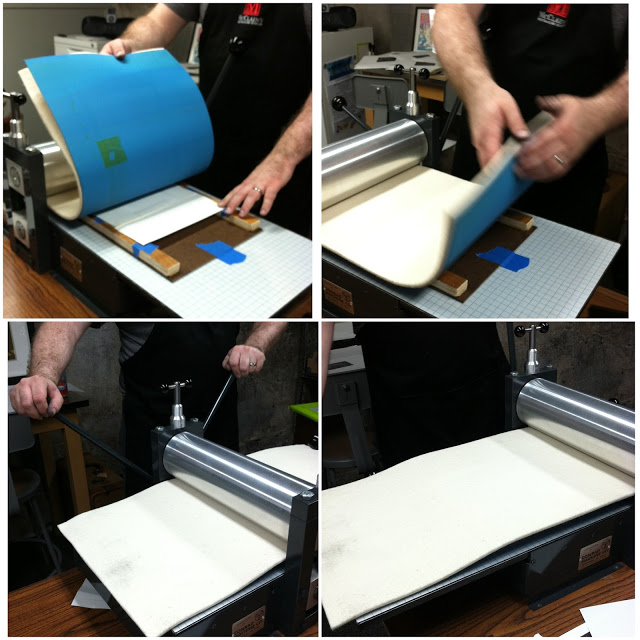

Once the block was cut, it was time to start the actual posters. There were a few steps to making these guys. I started with 120lb 11x17in. white card stock purchased locally. I decided to screen print the card stock first, leaving a large matte color block on the paper. I mixed a cement grey acrylic ink and flecked some gold and Prussian blue onto each screen as I printed. It gave the effect of each poster being slightly unique.

I printed 50 of these and hung them for a few days to completely dry. The paper now had a matte flat grey surface and a white paper border.

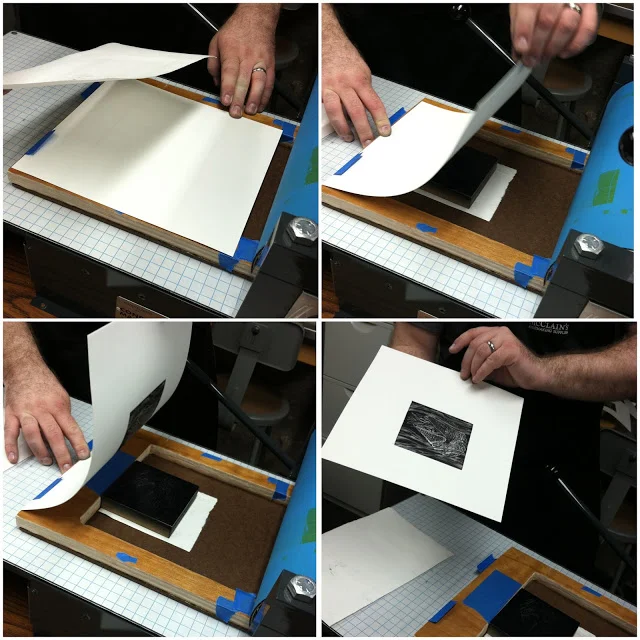

Time for round two! Once dry, the papers were ready to have the linoleum block letterpress printed on them. I used an oil-based black relief ink for the linoleum cut. The ink was rolled onto the surface of the linoleum in a thin even coat making sure the larger flat areas received plenty of ink.

Ink Slab

Rolling on the Ink

Registering the block on Press

The inked linoleum was then put on the press bed and a sheet of the screen-printed paper was placed onto the surface. I use a variety of registration systems to make sure the linoleum matches up with the grey surface of the paper. For this project I used some masking tape to help align the paper and block. Then they went through the press using a rubber blanket to get some nice embossing on the poster.

The paper is pulled off of the block and hung to dry.

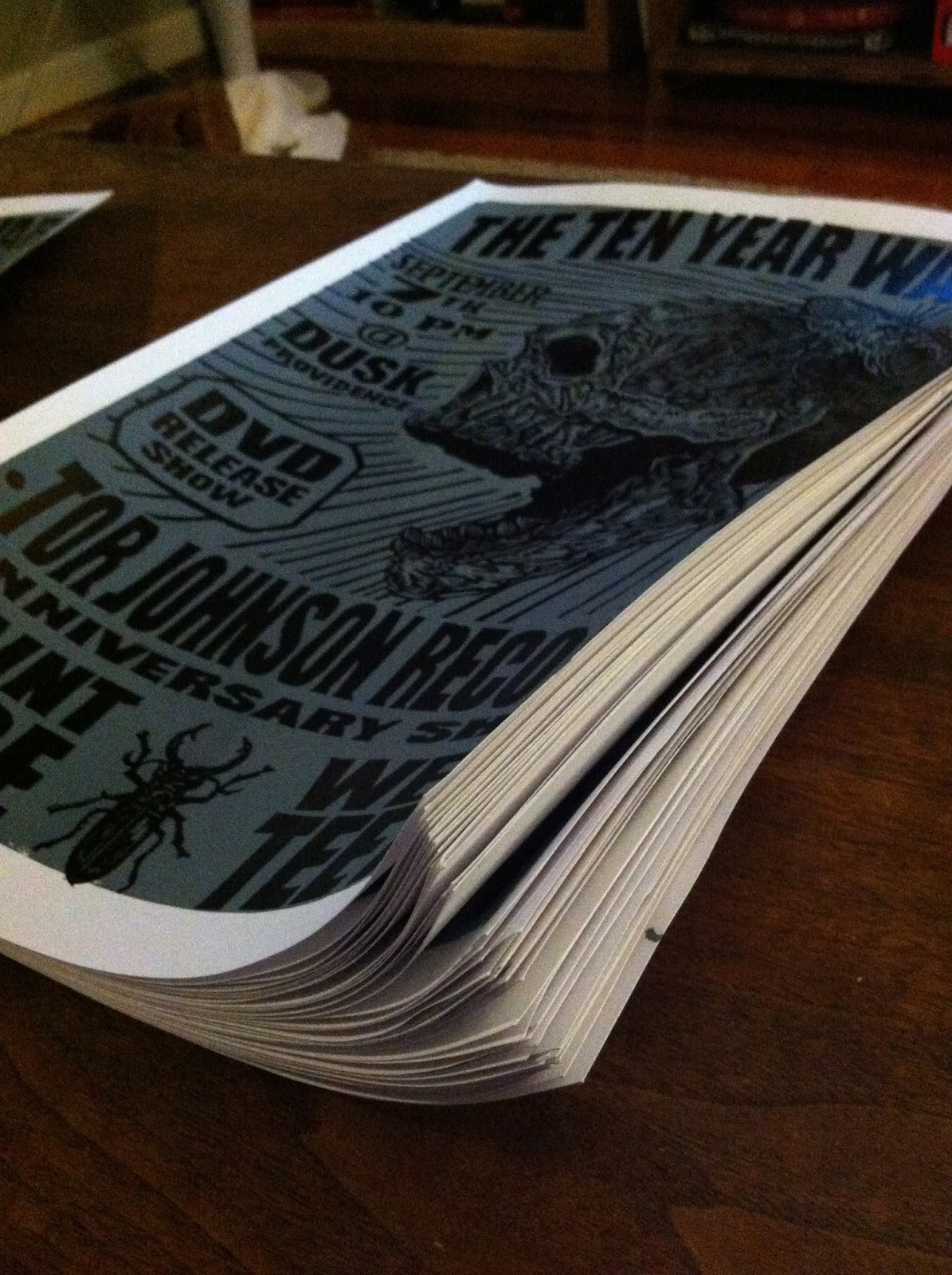

So. Many. Posters.

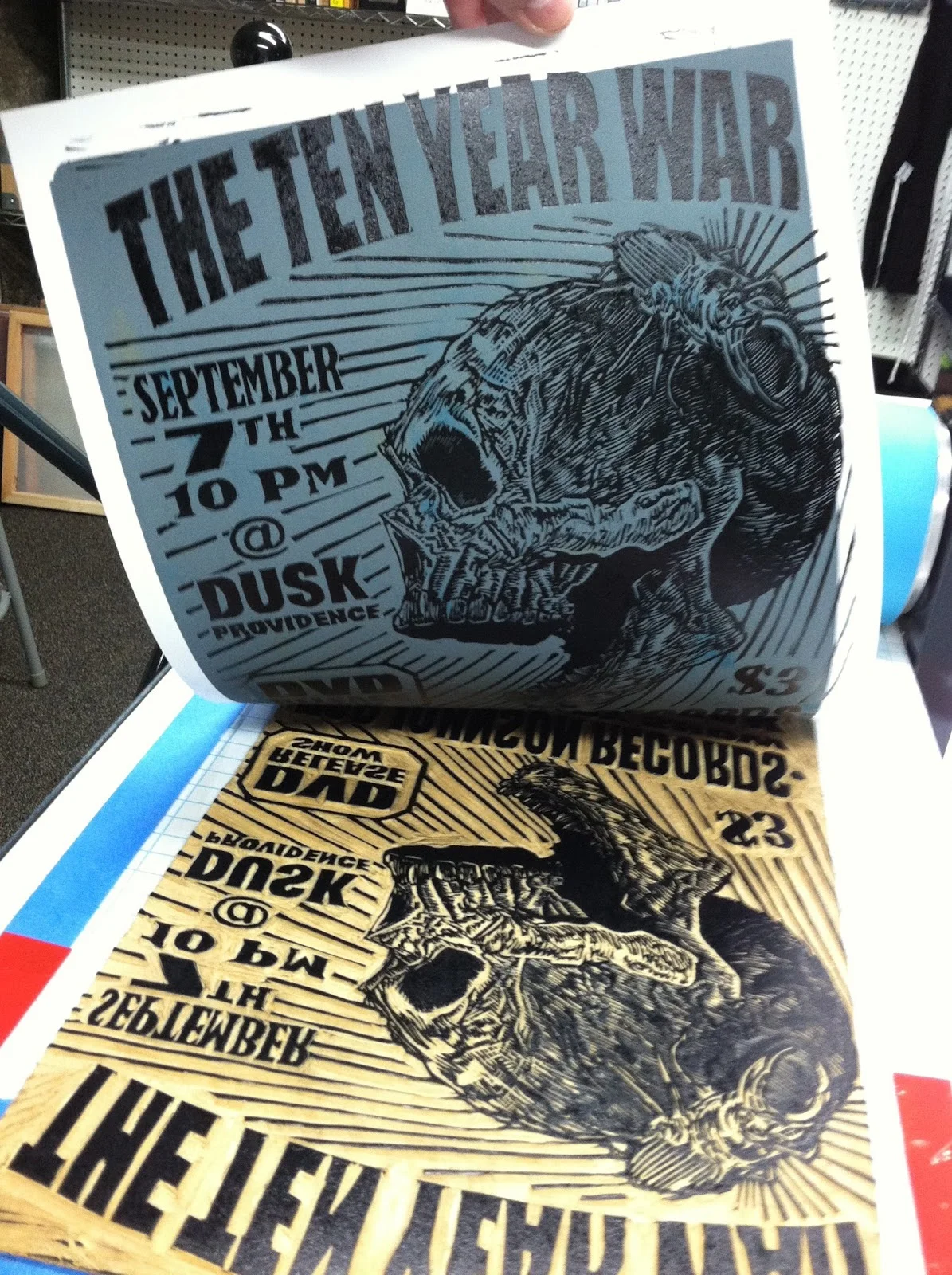

One of the coolest features on these posters was the sheen on the surface of them. Because I used a glossy oil-based black ink for the linoleum block and printed it on the matte screen printed grey paper, the lettering and skull looked wet and shiny! They almost had a warm silver look to them. This was an experiment using both processes in one poster and it came out great.

When the edition was complete and drying, I had to clean the linoleum block. I decided in true DIY punk fashion that I should make a patch on an old shop rag to give Paul when I dropped off the posters. What I should have done was stop messing around and cleaned up the shop, as I had been down there for almost 9 hours at that point! Paul dug the patch! Well worth it!!

So here is the finished poster. Again, every one is slightly different because of the random blue and gold flecks as well as the scuffed up bottom of the grey inked section.

This project was so killer!

I really look forward to some future projects with Paul and Tor Johnson Records. Check out their website if you are in the mood for some heavy music and killer records! There may be a few of these posters still available too!